Master-Bilt® Refrigeration News & Product Information

Refrigeration U: The Basic Refrigeration Cycle

Ever wonder what a screed is or how a compressor works? What’s an R-Value or a thermostatic expansion valve? We’re here to help you find the answers! Welcome to Refrigeration U, a new resource created to explore components, processes and terms found in the fascinating world of refrigeration. Got an idea for a topic? Drop us a note and share your thoughts.

Refrigeration Defined

During the summer there’s nothing better than a refreshing cold beverage. Daily, most of us will stop by a favorite local store for a cold drink of some kind. As you open the glass door refrigerator in the store and make your selection, you’ve probably never stopped to think about the process behind keeping that beverage cold.

Refrigeration is a vital part of our daily lives. Many aspects of life from food safety to medicine production to computer manufacturing all depend on refrigeration. But how does it work? In this article, we will explore the basic refrigeration cycle and its components. Note that we will touch on the basics only and leave more in-depth discussions of components for future articles.

So, what is refrigeration, anyway? There is a common misconception that refrigeration is about making things cold. Actually, it is the process of taking heat from someplace we don’t want it and moving it to someplace where it doesn’t matter. We refer to this process as the refrigeration cycle and, with some variations, it occurs within all refrigeration equipment.

The refrigeration cycle requires four main components:

- The compressor

- The condenser

- The metering device

- The evaporator

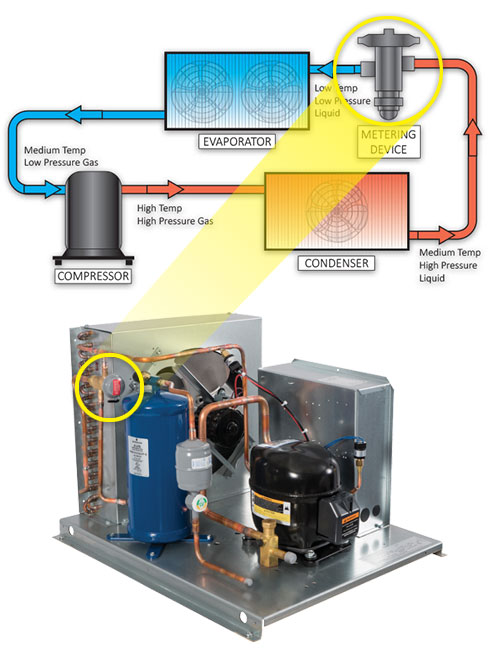

Refrigerant passes through these components in a continuous loop, or cycle, beginning with the compressor. Refrigerant is alternately a gas or liquid depending on its location within the cycle. Its pressure will also vary depending on location. The diagram below illustrates the cycle and the temperature and pressure of refrigerant as it goes through the loop.

The basic refrigeration cycle depends on four main components: the compressor, the condenser, the metering device and the evaporator.

The Compressor

The compressor is a pump that increases refrigerant pressure by decreasing or “compressing” its volume. The refrigerant enters the compressor as a medium temperature, low pressure gas and exits as a high temperature, high pressure gas. After compression, the compressor discharges the refrigerant to the condenser.

The compressor is a pump that compresses and moves refrigerant. This graphic shows the position of the compressor on a typical condensing unit.

The Condenser

The condenser is the point in the cycle where heat is removed from refrigerant. The condenser is a coil of tubing, typically copper, with metal fins and a fan. As refrigerant gas travels through the length of coil, heat is dissipated, or rejected, causing the gas to condense into a high-pressure liquid. The fins provide a metal surface to more efficiently absorb heat while the fan blows air across the coil to remove it. From the condenser, the pressurized liquid moves to the metering device.

The condenser is the point in the refrigeration cycle where heat is removed from refrigerant.

The Metering Device

The metering device, usually a thermostatic expansion valve or a capillary tube, controls the pressure of the liquid refrigerant as it enters the evaporator. Refrigerant pressure must be lower before entering the evaporator and, as the metering device lowers the pressure, the temperature is also lowered.

The purpose of a metering device is to control the pressure of liquid refrigerant as it enters an evaporator.

The Evaporator

In the last stage of the cycle, the refrigerant gas reaches the evaporator. Like the condenser, the evaporator is a coil of tubes with fins and fans, but its purpose is to absorb heat, the opposite of the condenser. Within the evaporator, the low-pressure refrigerant starts to expand as it absorbs heat from air that passes over the coil (blown by fans), changing its state from low pressure liquid back to gas. This change in state from liquid to gas is called evaporation.

In the evaporator coil, refrigerant changes its state from low pressure liquid back to gas.

The Cycle Restarts

When air temperature inside the cooler or freezer reaches the desired limit, the thermostat or electronic controller will cause the compressor motor to shut off. As the air temperature rises, as determined by sensors in the evaporator, the thermostat or controller restarts the compressor and the cycle begins again.

Moving Heat

As you see, the refrigeration cycle is all about moving heat into and out of refrigerant. The compressor introduces heat, the condenser removes it and the evaporator brings it back. In the end, we move the heat from the space that we want to be cool to somewhere else.

So next time you pick up your favorite beverage, remember there’s more to keeping it cold than meets the eye.